Working condition

| Pressure Rating | CLASS 150 to CLASS 900 (PN 10 to PN 150) |

| Nominal Diameter | NPS 3 to NPS 60 (DN 80 to DN 1500) |

| Seat Leakage Class | ANSI FCI 70-2 CLASS VI or better |

| Applicable Media | Liquid phase, gas phase, hard abrasive particles |

| Temperature Range | ≤750°C |

| Fireproof & Anti-Static Design | Support |

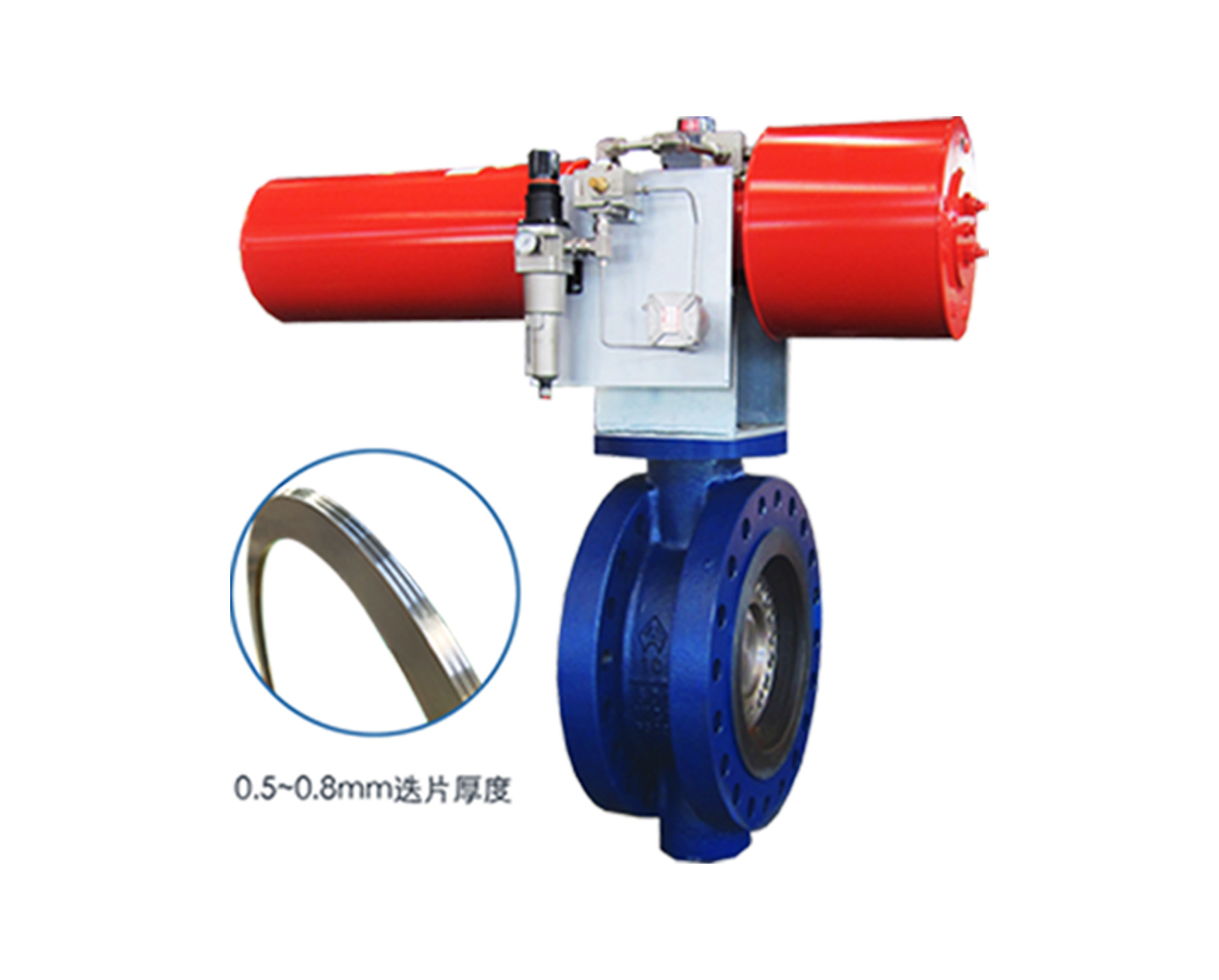

| Operation Method | Pneumatic, manual, electric, hydraulic |

Pain Points and Proposal

1. Internal Leakage:

① Under high-temperature working conditions, the expansion amounts of the plate and the stem are inconsistent, resulting in poor fit between the seat ring and the disc.

② To achieve a good sealing under high-temperature conditions, the closing torque of the actuator is excessively large, resulting in high pressure on sealing surface. The higher the pressure on the sealing surface, the higher the possibility of wear, creep, overload, and metal adhesion. It increases the probability of damage on the sealing surface and the iinternal leakage.

③ Excessive locking force on the seal ring retainer prevents the seal ring from achieving its self adaptive adjustment.

2. Jamming:

① Metal galling and heat accumulation on hard alloy sealing surfaces easily occur under high temperatures which causes scratches between valve disc and seat.

② Metal galling and heat accumulation on hard alloy sealing surfaces easily occur under high temperatures which causes scratches between valve disc and seat.

Reference