corrosive-resistent metal...

×

Consult

Working condition

| Pressure Rating | CLASS 150~900 |

| Nominal Size | NPS 0.5"–24" |

| Sealing Standard | API 598 / FCI 70-2 Class VI |

| Applicable Media | Acidic Slurry |

| Material | TiGr10 (Grade 10 Titanium) |

| Temperature Range | -5°C to +300°C |

| Operation Method | Pneumatic, Manual, Electric |

Pain Points and Proposal

1. Jamming, Internal Leakage, Short Service Life:

1.1 Seat coating corrosion/spalling

1.2 Seat sealing surface scratches

1.3 Spring corrosion failure

1.4 Solid buildup on ball

2. External Leakage:

1.1 Body flow path erosion

1.2 Body corrosion

1. Jamming, Internal Leakage, Short Service Life:

2. External Leakage Solution:

Body flow path liner insert with bonding-resistant coating surface

Reference

-

CIS-R

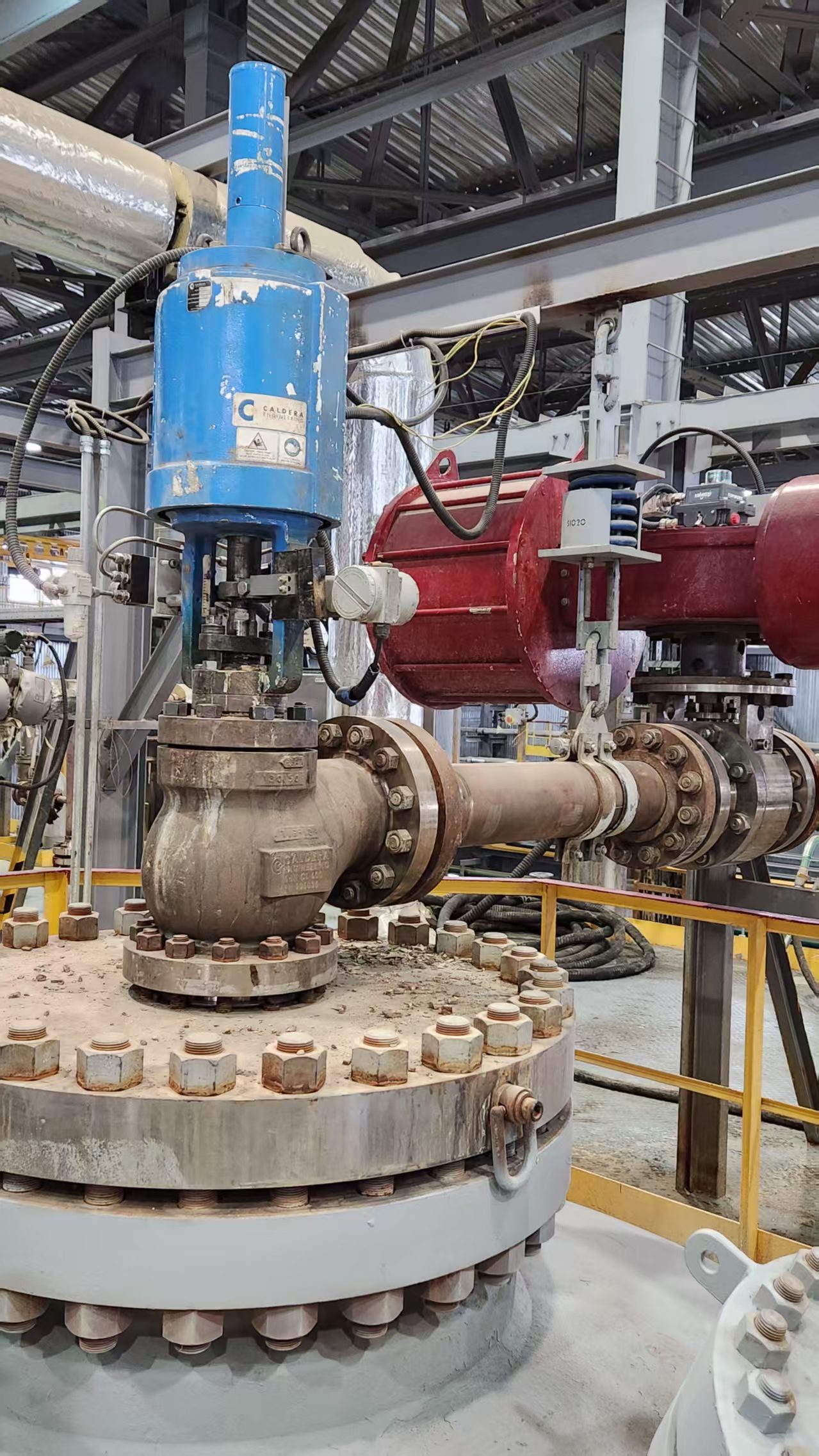

Process: Hydrometallurgical gold extraction

Size: NPS 6

Pressure Rating: CLASS 600lb

Temperature: 260°C

Fluid: Mineral Slurry with Acid

Raw material: Ti10