Working condition

| Pressure Rating | CLASS 150 – CLASS 900 |

| Nominal Diameter | NPS 6 – NPS 60 |

| Internal Leakage Standard | API 598, FCI 70-2VI |

| Applicable Media | Gaseous, Liquid |

| Temperature Range | -50℃ to -425℃ |

| Operation Methods | Pneumatic, Manual, Electric, Hydraulic |

Pain Points and Proposal

1. High leakage rate & Short service life:

① Excessive valve torque creates elevated sealing surface pressure, significantly increasing risks of galling, creep deformation, overload damage, and adhesive wear. This accelerates sealing surface degradation, heightening internal leakage probability.

② Poor fitting degree between seat ring and disc ring causes stress concentration.

2. Repair Limitations:

① Seat/disc ring interfaces feature irregular conical surfaces with non-replicable eccentric angles. Without precise cone angle and dimensional chain tolerance data, repair integrity cannot be guaranteed.

② Fixed seat design prevents disassembly for maintenance.

③ Seal rings and seats lack interchangeability across product lines.

3. Fail to Achieve True Bi-directional Sealing:

4. Passing Factory Acceptance Tests but Failing In-Service:

Blind flange pressure testing yields false positives due to large cavity volume – bubbles cannot traverse conduits within standard test durations, masking leakage.

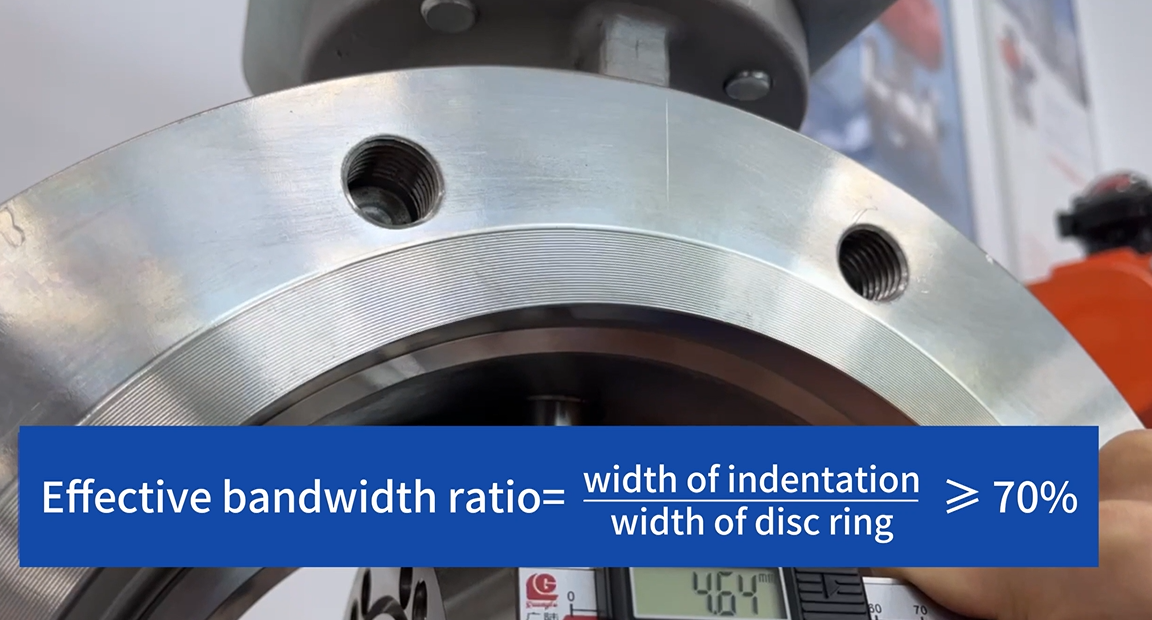

Real zero leakage triple offset butterfly valve| Effective bandwidth ratio

Reference

-

Henan Energy Group Co.,Ltd.

Process:PSA process

Size:DN400

Temperature:40℃

Pressure Rate: CLASS 300

Fluid:hydrogen and carbon monoxide

Raw material:WCB -

Shaanxi Changqing Energy Chemical Co.,Ltd

Process: GE-TEXCO Gasification

Size: DN700

Pressure Rating: CLASS 900lb

Fluid: syngas

Temperature: 275°C

Raw material: CF8M