Working condition

| Pressure Rating | CLASS 150 to CLASS 1500 (PN 10 to PN 260) |

| Nominal Size | NPS ½ to NPS 16 (DN 15 to DN 400) |

| Seat Leakage Class | ANSI FCI 70-2 CLASS VI or higher |

| Applicable Media | Gas phase |

| Temperature Rating | Up to 220°C |

| Cycling Life | 100,000 to 1,000,000 cycles per year |

| Stroking Speed | Typically 1–3 seconds (faster speeds available upon request) |

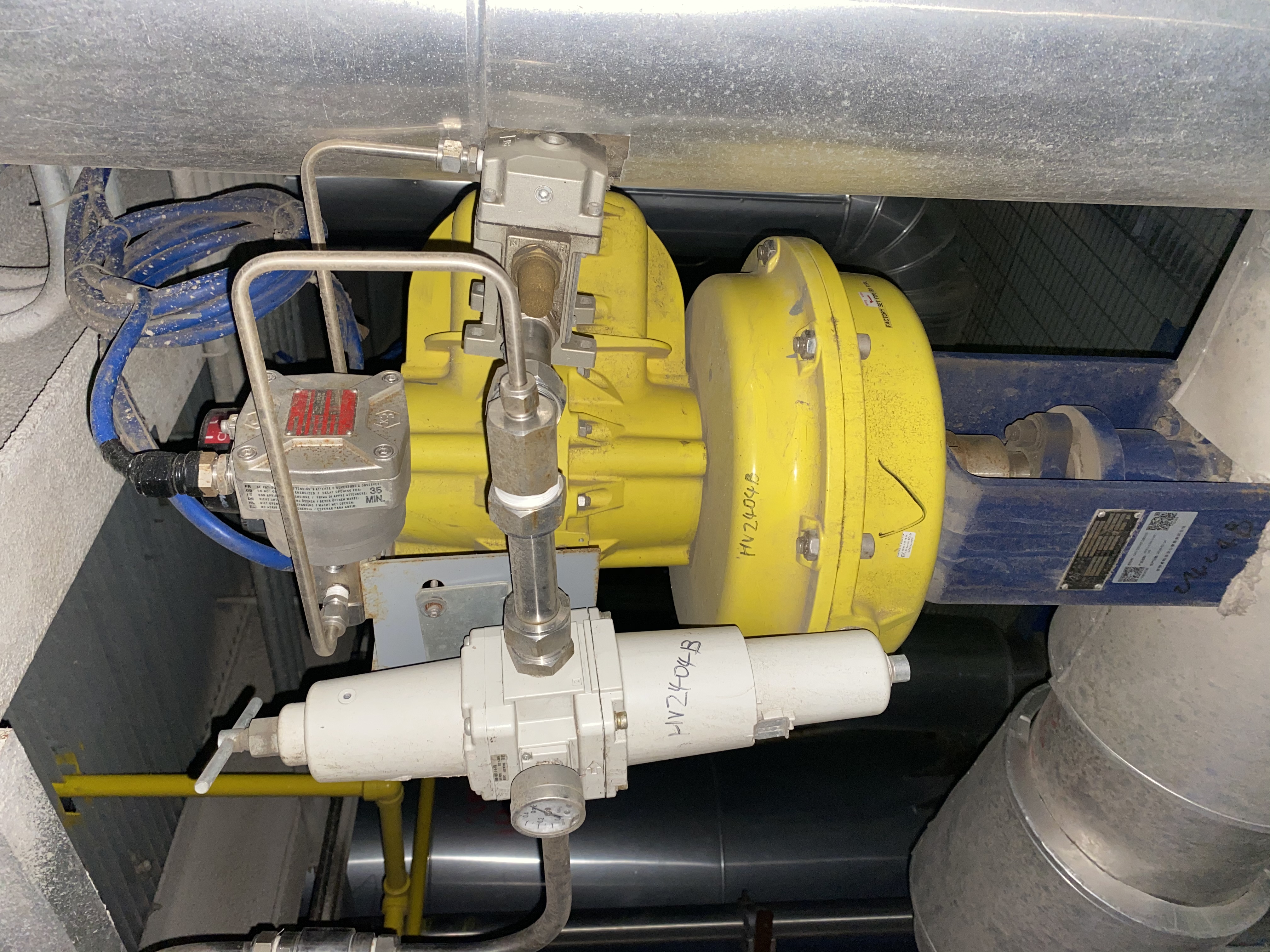

| Actuation Methods | Pneumatic, Hydraulic |

Pain Points and Proposal

1. External Leakage: packing wear due to frequent opening/closing without any compensation, finally external leakage occur.

2. ① High-frequency opening and closing as well as high-speed movements are likely to cause bonding of metal sealing pairs, resulting in premature damage.

② Solid powders in the medium tend to accumulate in the spring chamber, causing the valve's opening and closing torque to gradually increase, thus leading to jamming.

③ Ultra-fine particles easily accumulate in bushings, bearing pocket, seats, etc., causing scratches on the stem surface, increased valve torque, or even cannot operate the valve.

3. Internal Leakage:

① High-frequency cycling and rapid actuation easily cause premature damage due to metal to metal "bite" by sealing surface pairs.

② Wrong dimensional tolerance chain design leads to inconsistent product quality.

2. Bow-groove ball design

3. Hardened flow-path liner

Reference

-

● CLASS 150lb & 300lb, sizes from 1.5” to 10”;

● Antewei supplied all 25 pneumatic valves;

● Commissioned in May 2020, operating flawlessly to date.