×

Consult

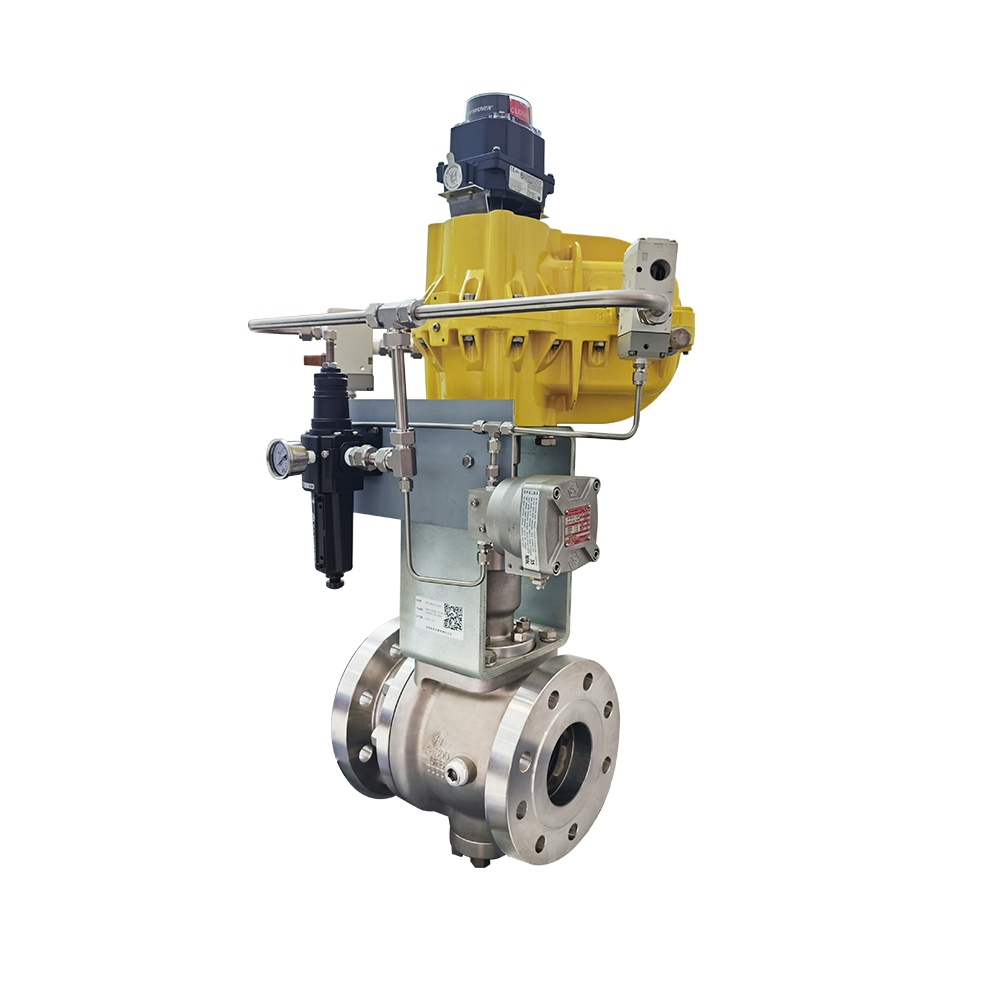

Quick on/off operating Means Long Service Life

Qualified PDS valve vendorr approved by Lummus for its Novolen-Polypropylene process;

Mixture coatings with no jamming even under long time frequently on/off operating;

Real live-loaded packing design to compensate packing wearing real-time with zero external leakage;

Enough references in many PE/PP projects, and replaced lots of PDS valves which were originally supplied by Metso/Flowserve/KTM.

High frequently operated ball valve (average 300,000 cycles per year and even more than 1.6 million cycles annually) is widely used in chemical industry where frequently on/off operating is needed, especially at PDS (Products Discharge

System) unit in PP (polypropylene) or PE (polyethylene) plant. Antiwear has done lots of research on sealing surface metal alloy coating which can meet frequently operating application based on plenty of testing and experiments. Besides that, optimizing structural design and manufacturing process takes themetal-seated ball valve a long service life of up to 3 million cycles, which would be the best choice

for high-frequently operating applications.

Parameter

| Pressure Rating | CLASS 150~CLASS 1500(PN10~PN260) |

| Nominal Diameter | 1/2〞~16〞(DN15~DN400) |

| Temperature Range | -60℃~150℃ |

| Body Material | carbon steel, stainless steel, duplex steel, etc. |

| Ball Material | F304/F316/ duplex +H.F, etc. |

| Spherical Material | F304/F316/ duplex +H.F, etc. |

| Operation | pneumatic |

Application

- Application: Petrochemical

Process: Innovene PP Process/Size: DN50/Pressure Rating: CLASS 300 lb/Operating Temperature: 150°C/Medium: Polypropylene PowderMaterial: F316SSSwitching Frequency: 240 cycles/hourService Life: >2 years- Application: Petrochemical