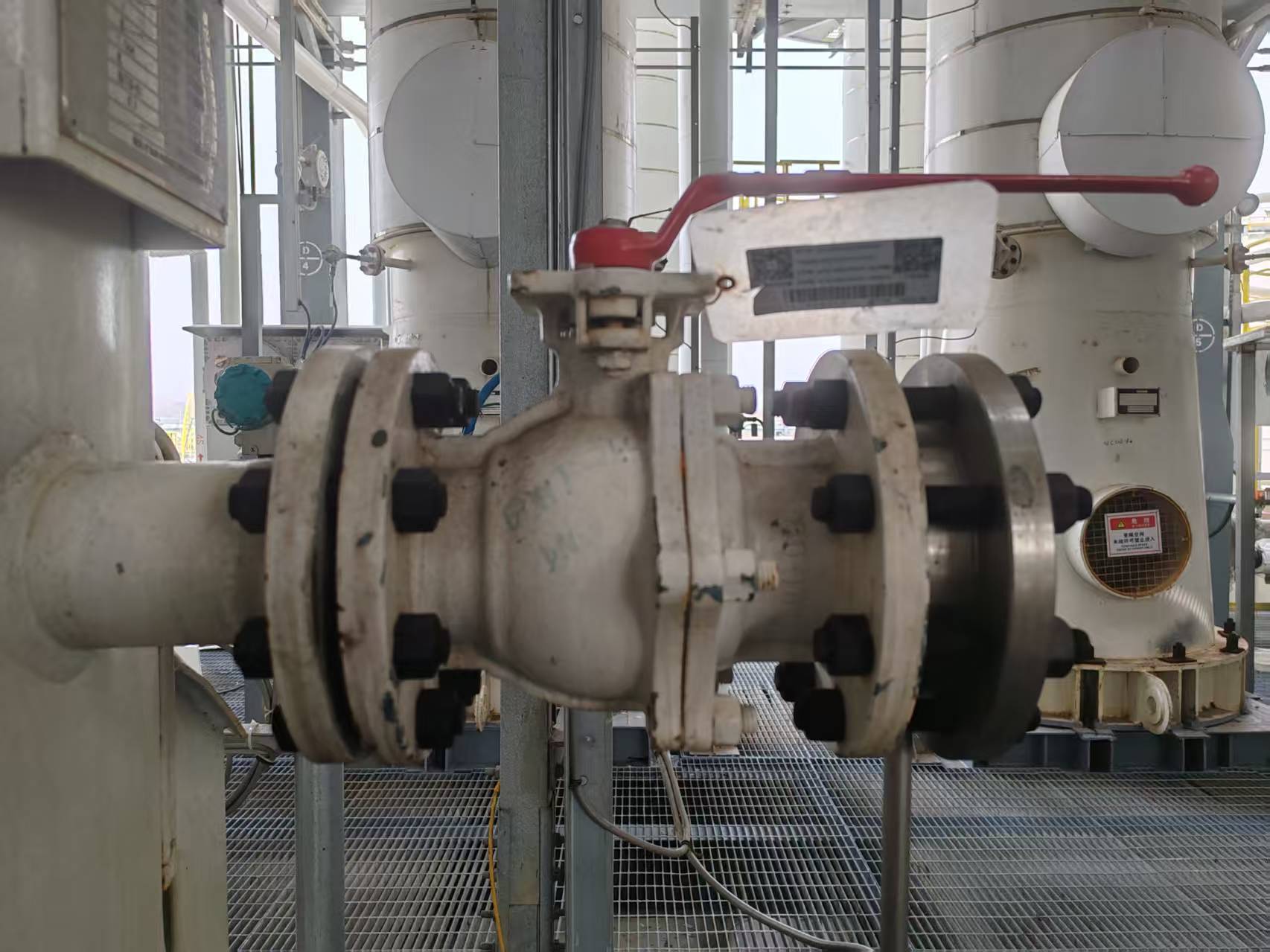

• Specifications: PN25–PN100, DN25–DN200;

a total of 80 phosgene soft-seal valves installed

• Operation: Commissioned in October 2023;

no external leakage reported to date, currently operating smoothly

Working condition

| Pressure Rating | CLASS150 ~ CLASS1500 (PN10 ~ PN260) |

| Nominal Size | NPS 1/2 ~ NPS 12 (DN15 ~ DN300) |

| Seat Leakage Class | ANSI FCI 70-2 CLASS VI and higher standard |

| External Leakage Performance | Compliant with ISO 15848 Class B |

| Applicable Media | Liquid/Gas Phases |

| Operating Temperature | ≤ 150 °C |

| Fire-Safe & Anti-Static | support |

| Operation | Pneumatic, Manual, Electric, Hydraulic, etc. |

Pain Points and Proposal

1.Toxic gases have strong permeability and are prone to cause external leakage through the middle flange of the valve.

2.Under the working condition of oil removal and degreasing, the packing wear cannot be compensated after the valve is opened or closed, resulting in external leakage.

1. Multi-Level Anti-Leakage Design

2. Live-loaded Bearing Packing Compensation design: Precise Wear Compensation Design Formula

Reference

• Specifications: PN25–PN100, DN25–DN200;

a total of 80 phosgene soft-seal valves installed

• Operation: Commissioned in October 2023;

no external leakage reported to date, currently operating smoothly